We manufacture with precision, dimensional accuracy and efficiency!

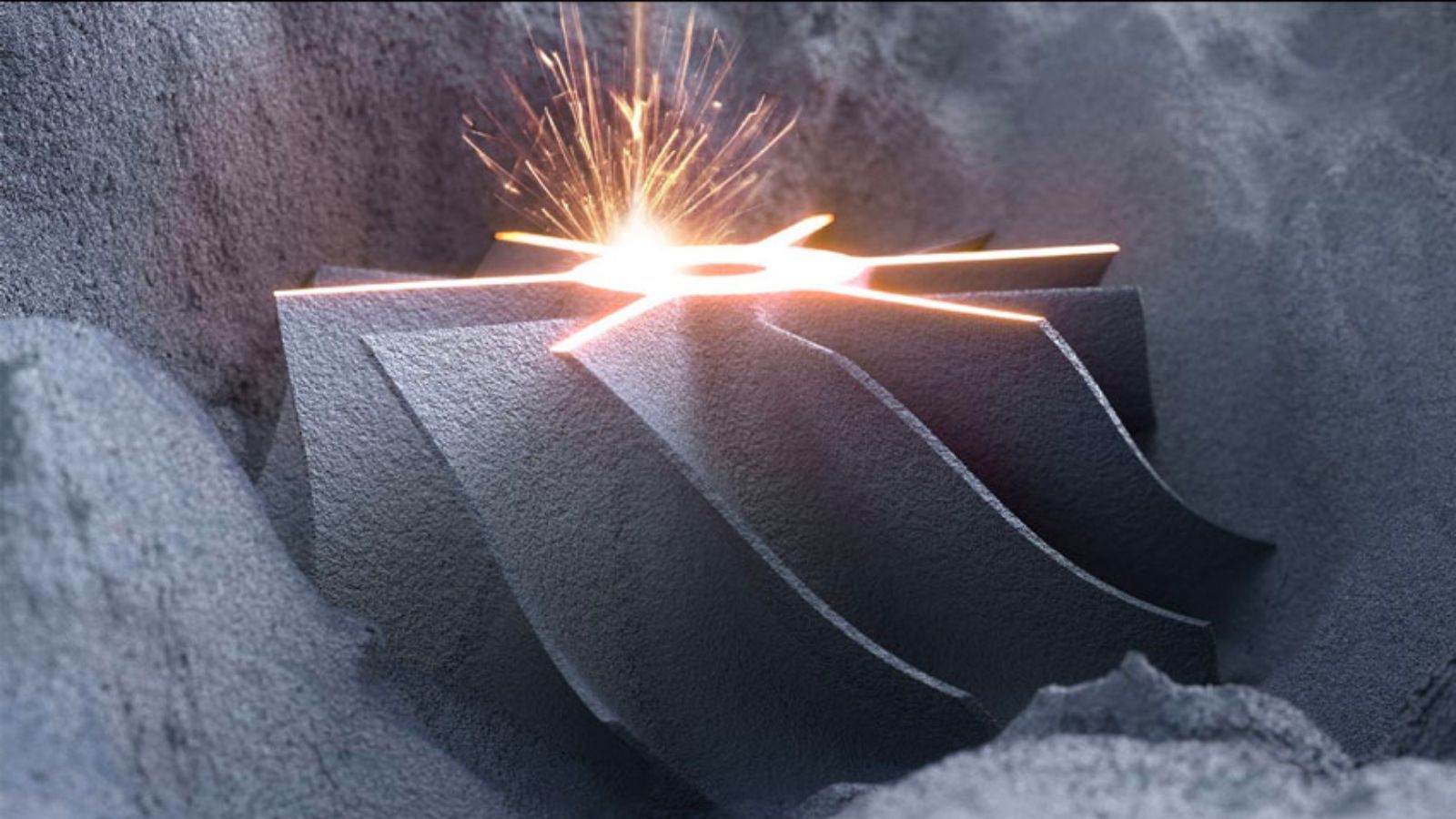

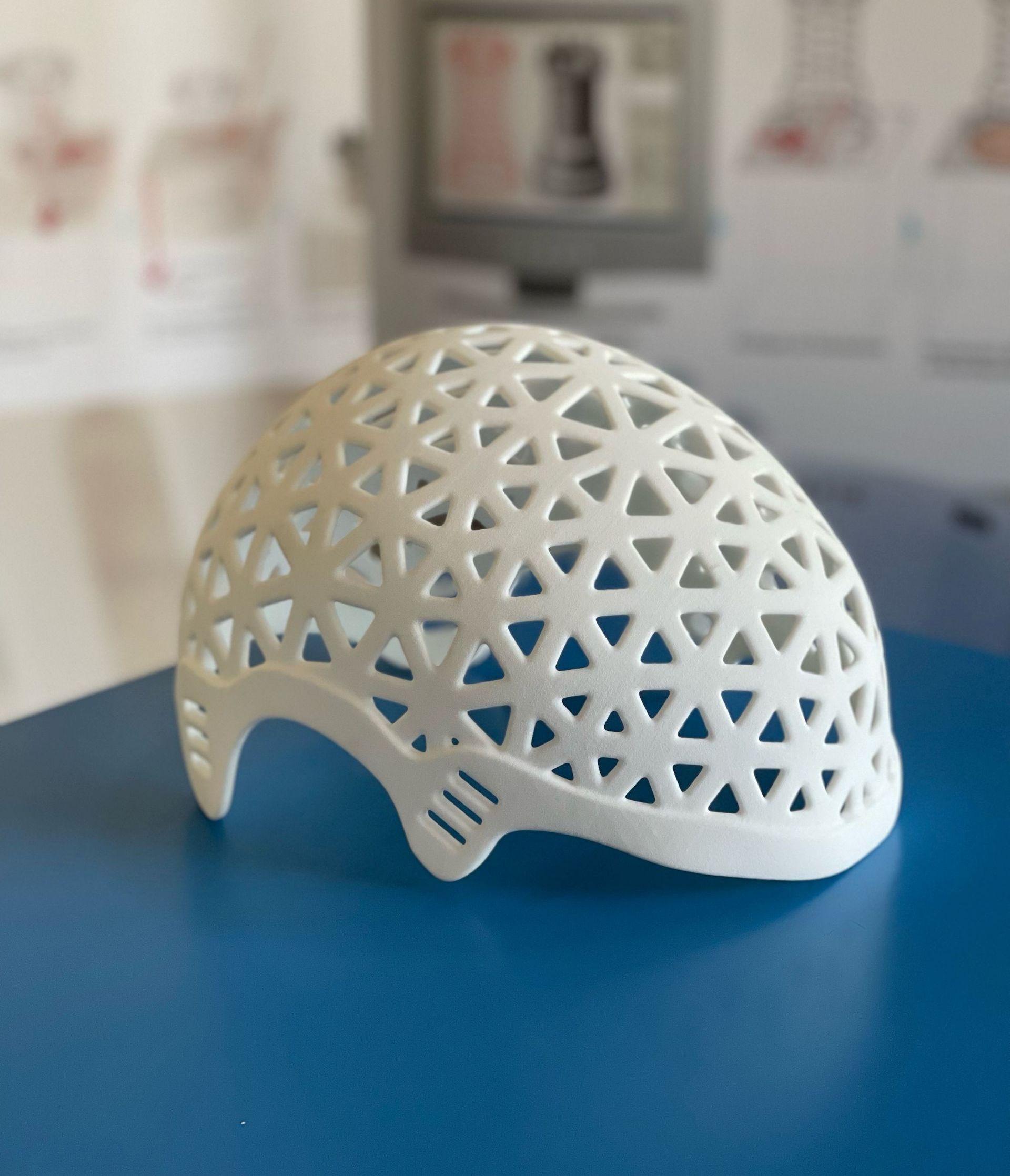

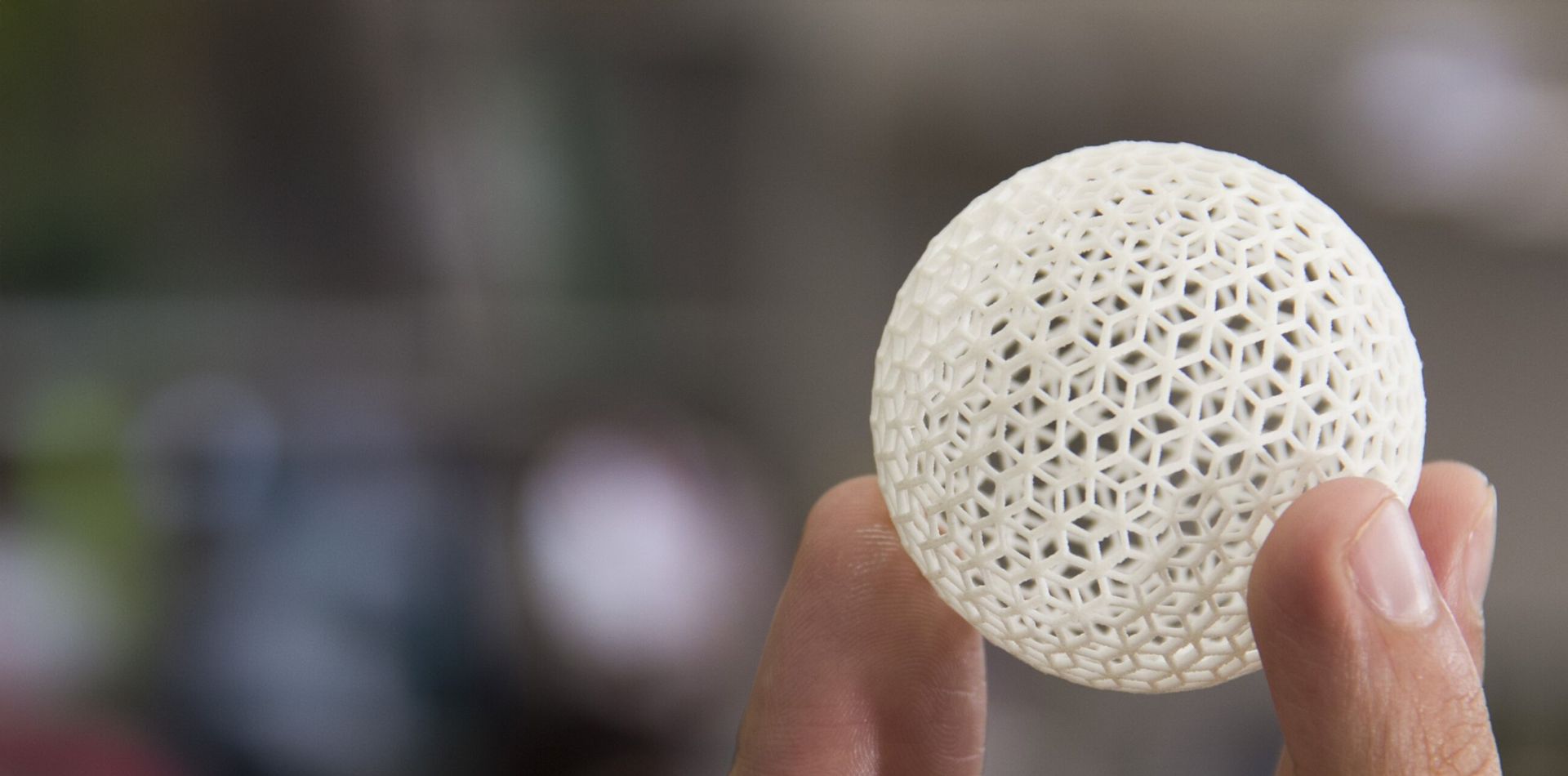

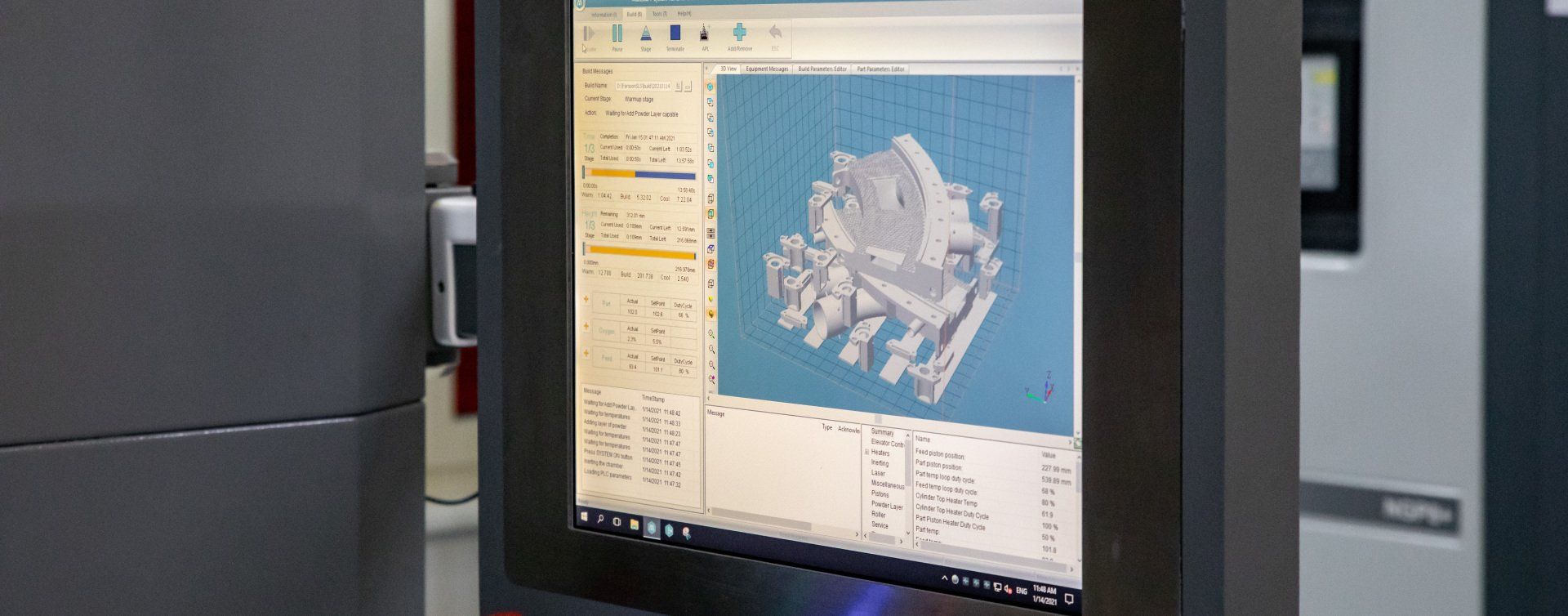

Using selective laser sintering (SLS), we manufacture your component layer by layer from plastic powder using heat and laser radiation. On request, the parts can be ground, dyed, impregnated, galvanized or mechanically finished.

Using the filament printing process with continuous fiber reinforcement - Continuous Fiber Fabrication (CFF) - we can produce high-strength components according to your requirements. This means that components with a strength similar to aluminum can be produced in the 3D printer in a very short time.

Express manufacturing

Yesterday or at least the sooner the better? Get your workpiece instantly!

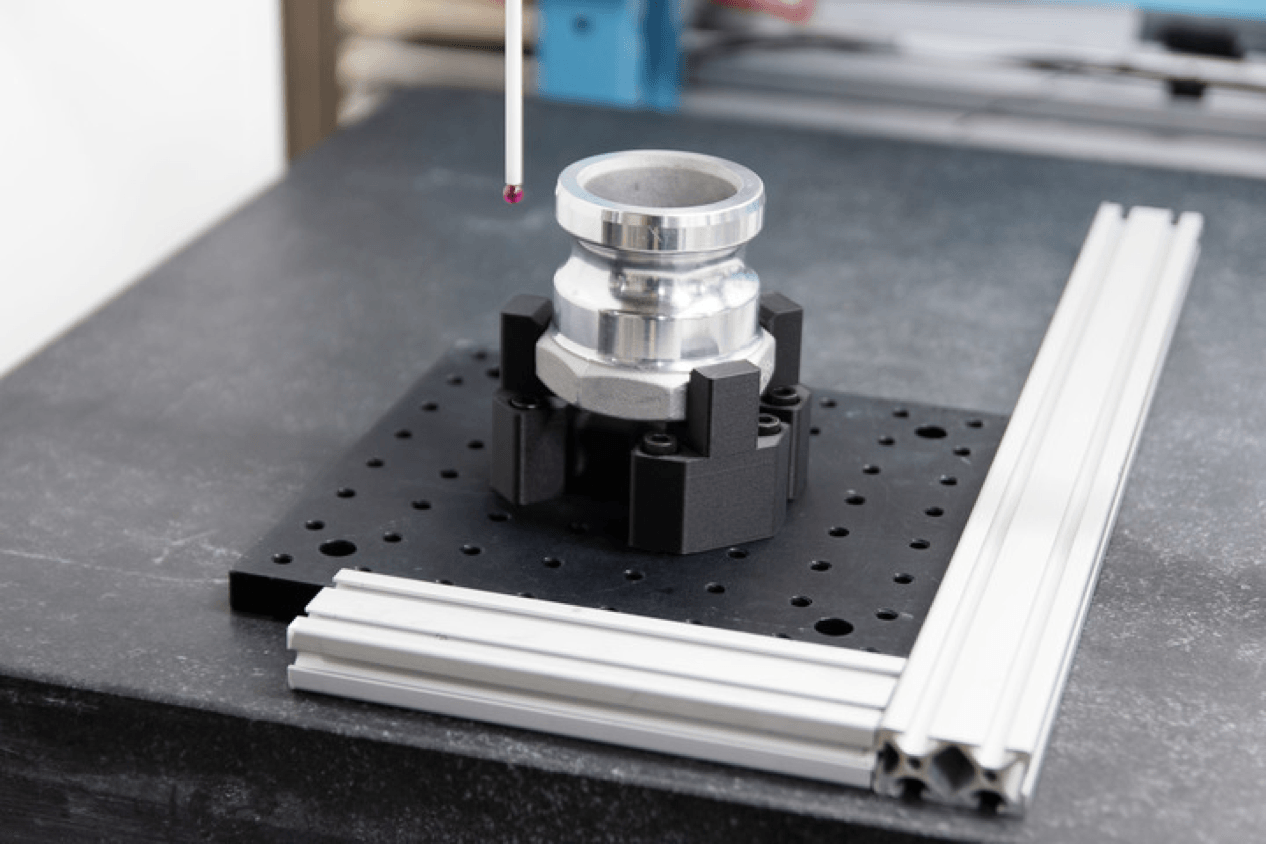

Series production

Do you need small, complex components made of plastic or metal, but don't want to or can't invest in a mould?

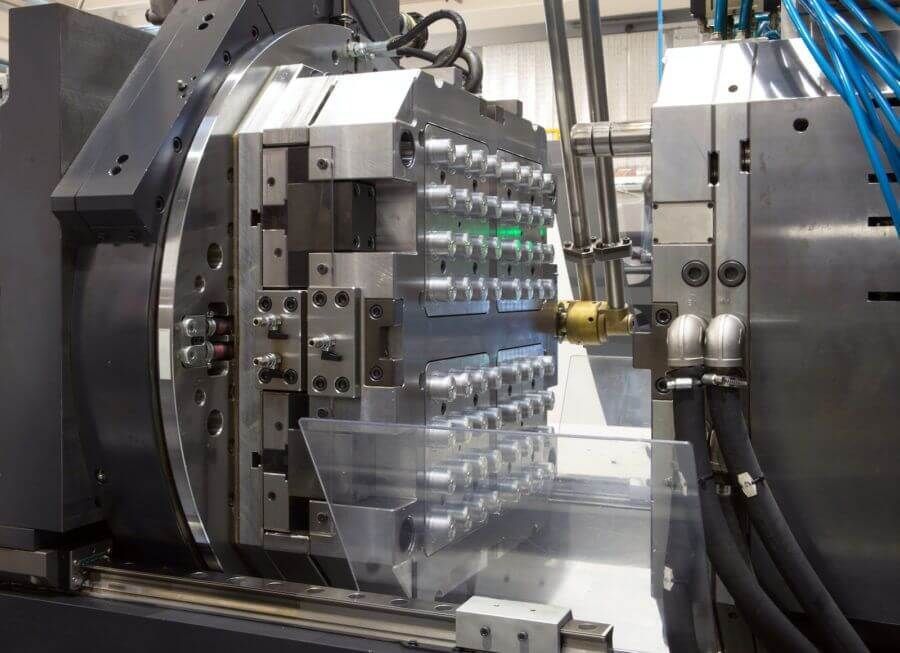

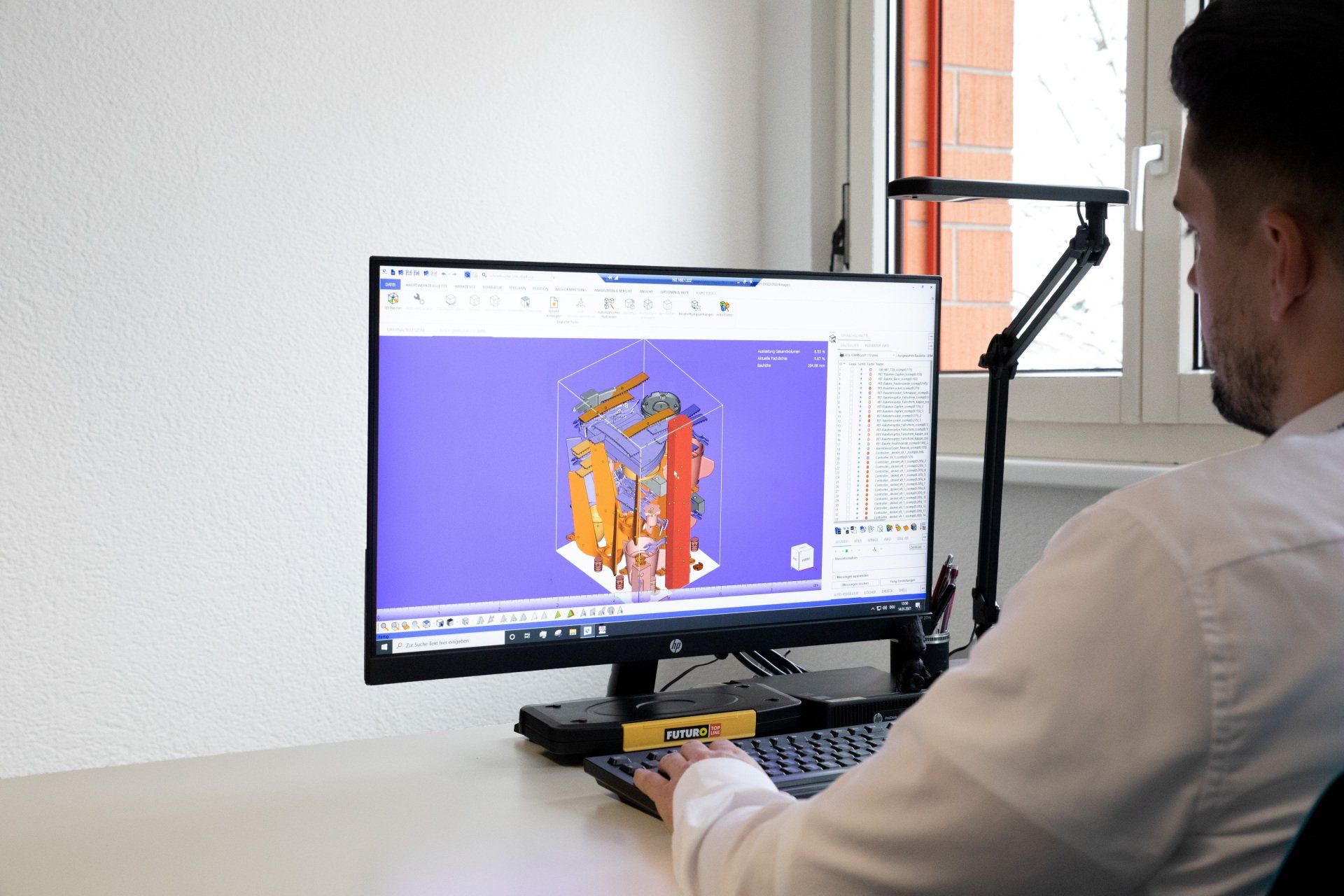

Rapid Prototyping

In less than a week to your prototypes? Or even by express overnight? Rapid Prototyping by Rapid Manufacturing is your answer!