GÖTTI DIMENSION - 3D PRINTED EYEWEAR

Exclusive and custom made eyewear frames

Rapid Manufacturing is production partner for the serial production of Götti Dimension.

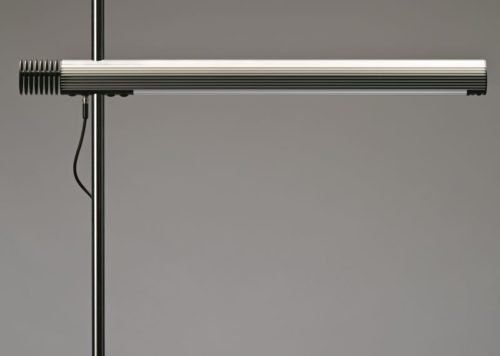

The Dimension collection combines innovative technology with the highest level of craftsmanship. From the idea and design to 3D programming and additive manufacturing to coloring and final assembly - every step is carried out with great care and experience. The modern and resource-saving processing results in extremely comfortable glasses in the typical Götti design language: innovative, minimalist and well thought-out.

Piece by piece - perfection through additive manufacturing

Additive manufacturing methods open up a wide range of new possibilities and offer plenty of creative freedom in the design process. The frames are manufactured with precision, are extremely light and yet particularly stable. Their uniformly matt surface gives them an elegant, timeless aesthetic.

State-of-the-art technology for the highest quality

It all starts with a precise design of the shape of the glasses, which is digitally modeled and converted into a printable 3D model. Production is carried out using state-of-the-art additive manufacturing methods, whereby the base material, polyamide, is built up layer by layer in the form of a fine powder using an industrial SLS printer. After several surface treatments, the final dyeing process ensures a lasting and uniform coloration.